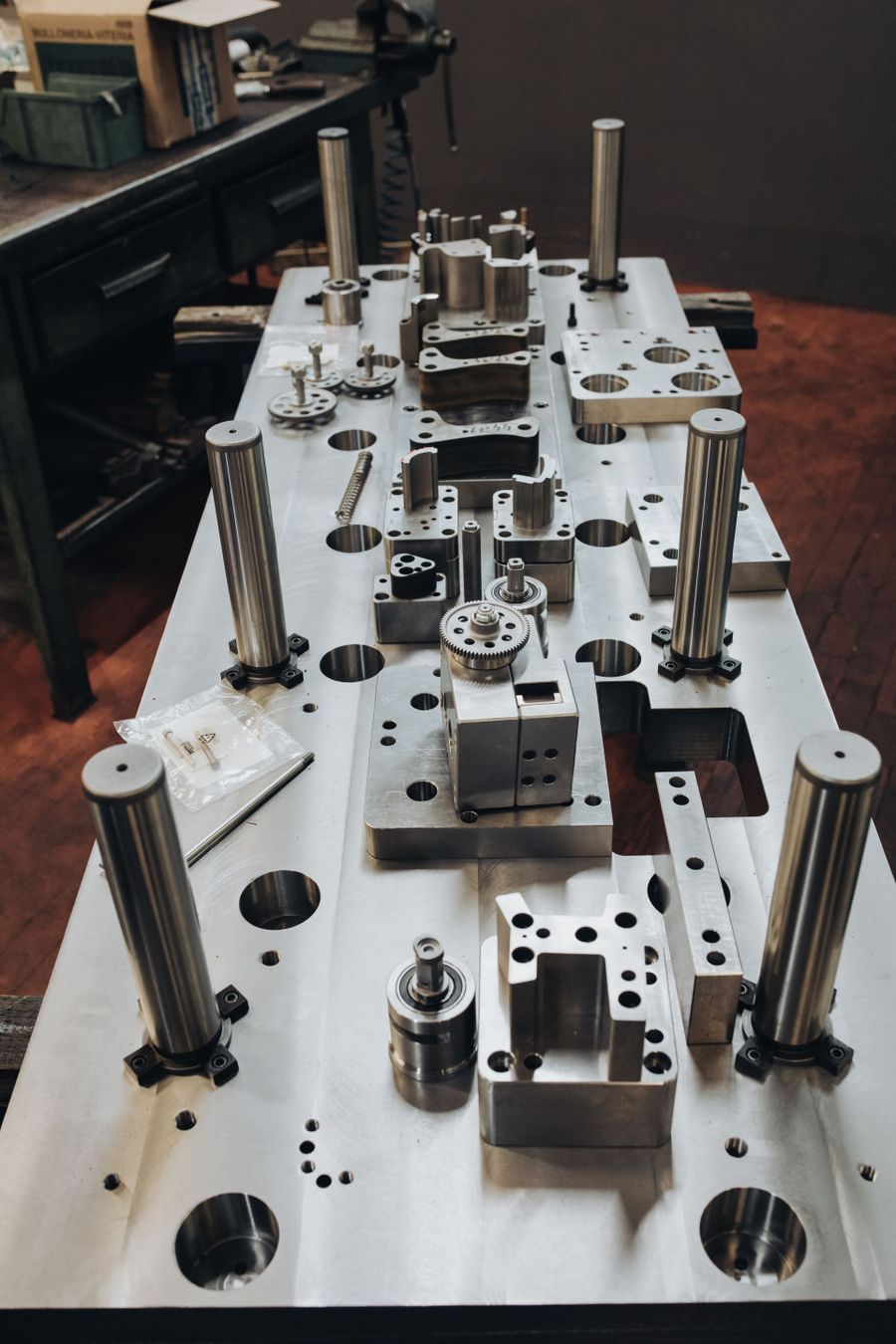

The internal tooling service is essential for meeting our clients' demands for new projects. Starting from the specific component design, we are able to design moulds for the production of parts, which takes place in the adjacent Stamping Department.

Moreover, the strength of our tooling capabilities lies in the ability to intervene during the production of moulds in Bologna in case of breakdowns or modifications requested by the client. This allows us to avoid production stoppages and maintain an uninterrupted production cycle.

Slide title

Write your caption hereButton

Titolo diapositiva

Scrivi qui la tua didascaliaPulsante

Titolo diapositiva

Scrivi qui la tua didascaliaPulsante

Titolo diapositiva

Scrivi qui la tua didascaliaPulsante

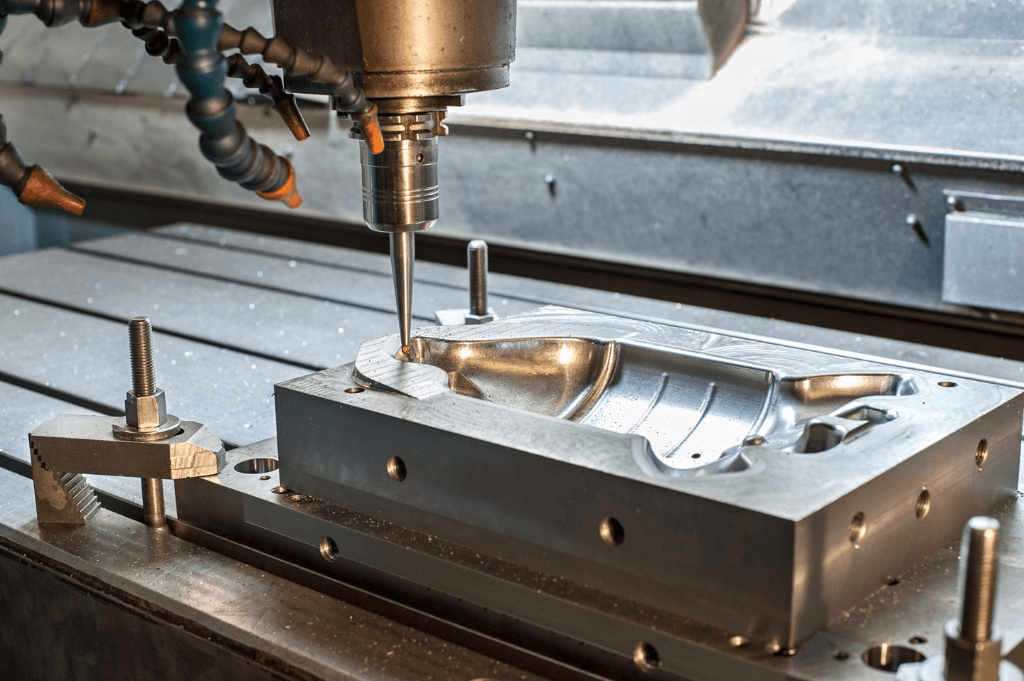

Moulds, punching tools, and deep drawing tools

for sheet metal deformation

Thanks to the use of sophisticated 3D design software and advanced CAD-CAM technologies, our technical office is equipped to develop simulations, prototypes, products, and highly sophisticated components for tooling and moulds. We also handle the creation of equipment for punching, progressive stamping, forming, and deep drawing of metals, paying particular attention to the various stages, from planning to the maintenance of the moulds during the production cycle.

We are capable of intervening for the revision or modification of moulds in production, ensuring a prompt response to issues with moulds in the adjacent Stamping Department. Additionally, we produce spare parts for high-production equipment to prevent production downtime.

Il servizio di Attrezzeria è in grado di supportare il Cliente nella Ricerca e Sviluppo per la realizzazione di nuovi progetti: chiama o scrivi per maggiori informazioni

HEADQUARTERS

Via Curiel 4

40069 Zola Predosa (BO)

OPENING HOURS

- Mon - Fri

- - -

- Sat - Sun

- Closed

VAT No. 00523911204 |

Legal Information |

Privacy and Cookie Policy